Description

Ball Screws Precision Seamless Ball And Lead Screw

Function Of Precision Ball Screw In Precision

Precision Ball Screw Accuracy Can Not Meet The Requirements Of How To Deal With:

The Ball Screw Has Been Checked For Accuracy When It Is Put Into Storage, Which Can Eliminate The Quality Problems Of The Ball Screw Itself. However, Slender Shaft Parts (Machine Tool Screw, Etc.) Should Be Placed Vertically In Storage To Avoid Gravity Deformation Affecting Accuracy. The Ball Screw Is Placed Vertically In The Special Packing Box, Which Is Qualified For Static Inspection After Assembly, So This Item Can Be Excluded.

Troubleshooting Methods For Precision Ball Screw:

1, After Using The Thick Hinges Of The Machine Hinges, The Allowance Of The Fine Hinges Must Be Set Aside, And Then The Fine Hinges Must Be Manually Made.

This Method Can Correct The Taper Error After The Hinge, Reduce The Surface Roughness Of The Hole Wall, Improve The Contact Accuracy Of The Mating Surface, And Ensure Sufficient Friction Moment.

2, When Reaming, The Taper Pin Should Be Matched In Time.

The Purpose Is To Facilitate The Control Of Reaming Hole Diameter Of Ball Screw. When The Taper Pin Can Be Inserted By Hand About 80%-85% Of The Length Of The Pin, The Aperture Is Qualified; After Cleaning The Iron Scraps, The Taper Pin Should Be Coated With Oil And Then Penetrated With Copper Rod To The Surface Of The Workpiece, In Order To Ensure Sufficient Friction Moment And Prevent Loosening Due To Load In Use.

3, Do a Good Job Of Dust-Proof Treatment On The Surface Of Ball Screw

In The Process Of Drilling, Reaming And Tapping Threads, Dust-Proof Treatment Should Be Done On The Surface Of Lead Screw. The Exposed Part Of The Screw Is Wrapped With a Clean Cloth To Prevent Dust From Entering The Transmission Surface Of The Screw Pair, So As To Prolong The Service Life Of The Precision Components And Improve The Assembly Accuracy.

Ball Screw Is An Ideal Product Which Converts Rotary Motion Into Linear Motion Or Linear Motion Into Rotary Motion.

Ball Screw Is The Most Commonly Used Transmission Element In Tool Machinery And Precision Machinery. Its Main Function Is To Convert Rotary Motion Into Linear Motion, Or To Convert Torque Into Axial Repetitive Force. It Also Has The Characteristics Of High Accuracy, Reversibility And High Efficiency. Because Of Its Small Friction Resistance, Ball Screw Is Widely Used In Various Industrial Equipment And Precision Instruments.

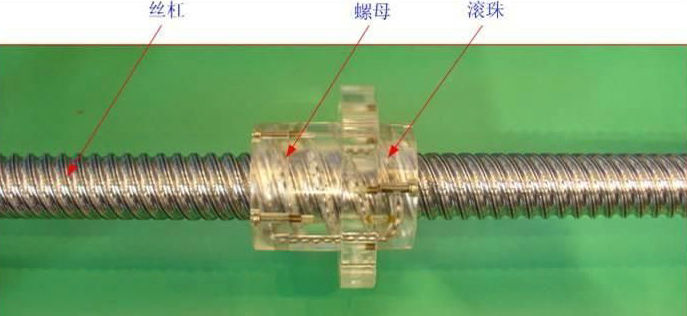

Ball Screw Is Composed Of Screw, Nut, Steel Ball, Pre-Pressing Sheet, Reverser And Dust Preventer. Its Function Is To Transform Rotational Motion Into Linear Motion, Which Is The Further Extension And Development Of Eckham Screw. The Important Significance Of This Development Is To Change The Bearing From Sliding Motion To Rolling Motion.

Ball Screw Bearings Provide a Variety Of Standardized Products For Various Purposes. It Is Widely Used In Machine Tools. The Circulation Modes Of Balls Are Circular Conduit Type, Circulator Type And End Cover Type. The Pre-Pressing Modes Include Positioning Pre-Pressing (Twin-Nut Mode, Positioning Pre-Pressing Mode) And Constant Pressure Pre-Pressing.

Appropriate Types Can Be Selected According To Their Use. The Screw Has Precision Ball Screw With High Precision Grinding (Accuracy Is Divided Into 6 Grades From Co-c7) And Cold-Rolled Ball Screw Bearing With High Precision Cold-Rolled Forming (Accuracy Is Divided Into 3 Grades From c7-c10).

In Addition, In Order To Cope With The Urgent Need Of Customers For Delivery, There Are Also Finished Products That Have Been Processed At The End Of The Shaft, Semi-Finished Products That Can Be Freely Processed At The End Of The Shaft And Cold-Rolled Ball Screw Bearings. As The Peripheral Parts Of The Bearing, The Necessary Screw Support Units, Nut Supports, Locking Nuts And So On Have Also Been Standardized For Users To Choose And Use.

Ball Screw Bearings Are Based On Product Technology Accumulated Over The Years. They Are Managed By Strict Quality Assurance System From Material, Heat Treatment, Manufacture, Inspection To Shipment. Therefore, They Have High Reliability.