Description

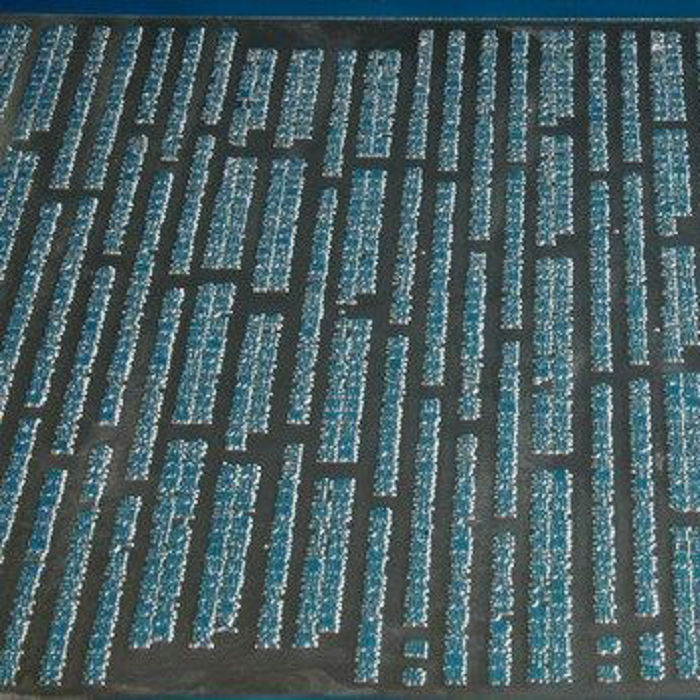

Etched Magnesium Plate Etch Mg Panels Sheet Mats Deck Media Etching

Etched Magnesium Plate Advantages Have Been Recognized Since It Was Put Into The Market In The Early 1970s. Later, With The Vigorous Development Of Printing And Packaging Industry, Etched Magnesium Plate Has Been Widely Accepted In The Field Of High-End Hot Stamping Printing. In Recent Years, Due To The Strict Requirements Of Environmental Protection And The Intensification Of Competition, Printing Enterprises Have Made High-Quality Metals. With The Continuous Improvement Of Template Material Requirements, The Application Of Etched Magnesium Plate Is More And More. The Application Fields And The Number Of Applications Are Growing Rapidly. There Is a Trend That The Traditional Copper And Zinc Plates Will Be Replaced By The Latter.

The Low Melting Point And Active Chemical Properties Of Magnesium Are The Difficulties And Bottlenecks Of Magnesium Alloying; The Dense Hexagonal Structure Of Magnesium With Few Slip Systems And Poor Deformation Performance At Room Temperature; The Preparation Of High-Performance Deformed Magnesium Sheets Requires Multi-Pass Isothermal Angular Rolling, Which Makes The Processing Cost Of Etched Magnesium Sheets High, Which Also Restricts Etching. Reasons For The Rapid Popularization Of Magnesium Plate.

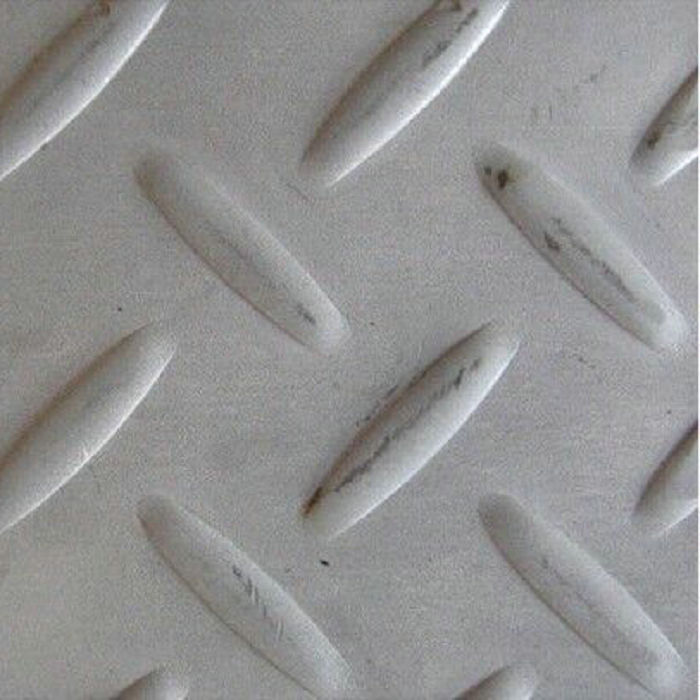

Magnesium Plate Has Small Specific Gravity, Light Weight, Fast Heat Conduction, Heat Transfer And Heat Dissipation, High Surface Hardness And Easy Demoulding; And In The Process Of Hot Stamping, Etched Magnesium Plate Hardly Deforms And Has High Printing Resistance; Etched Magnesium Plate Has Fast Corrosion Speed, Neat Slope, Good Continuity And Smooth Edge.

Magnesium Plate As a Corrosion Metal Material Has Many Advantages, Making Etched Magnesium Plate Widely Used In Printing, Packaging, Nameplate, Decoration And Other Fields Worldwide.

In The Paper Packaging Industry, Etched Magnesium Boards Are Used As Hot Stamping Plates And Bump Boards. The Same Size Template, Magnesium Plate Weight Is Relatively Light, Transportation, Installation, Gluing Board Are Convenient And Fast. The Heat Capacity Ratio Of Etched Magnesium Plate Is Small, The Effect Of Hot Stamping Is Good, The Gold Letters Are Bright, The Patterns Are Fine And Lustrous.

In Particular, The Hot Stamping Speed Of Magnesium Plate Is Much Faster Than That Of Copper And Zinc Plate, And The Printing Resistance Is 20% Higher Than That Of Copper Plate, Which Can Effectively Improve The Processing Speed And Save Labor Costs.

In Wine Box Paper Packaging Industry, Etched Magnesium Plate Can Be Used As Dent And Gilding Template. Its Good Printing Resistance And Heat Transfer Speed Can Greatly Improve Work Efficiency, Making Magnesium Plate For Corrosion Popular.

Large-Scale Etched Magnesium Plate Can Form Deep Embossing Template With Rich Layers, Fine Lines, Different Shades And Clear Stripes After Four Times Of Corrosion. It Can Be Used For Deep Embossing And Gold Stamping Of Heavy Paper Such As Wine Box Packaging, Moon Cake Box, Gift Box, Cosmetics, Book Cover And Bottom.

Refractive Embossing Lines On Corroded Magnesium Plate Can Be Directly Brushed Out With a Brush In Nitric Acid Of 5 Degrees. The Corrosion Speed Is Very Fast And The Operation Is Simple. It Saves The Procedure Of Corrosion Once Into The Corroder.

Especially, After Exposing Several Film At The Same Time, The Etch Is Clear And The Layers Are Rich, Which Saves The Process Of Degumming, Spraying, Exposing And Etching Magnesium Plate. Save Labor And Time.

After Hot Rolling And Tempering, The Thickness Of Magnesium Plate Is Uniform, And The Thickness Tolerance Is Very Small. The Anisotropy Of Magnesium Plate Is Basically Absent, Which Eliminates The Internal Stress Of The Plate. In Addition, The Yield Strength Of Etched Magnesium Plate Is More Than 200 Mpa, Which Is Stronger Than The Stiffness. Therefore, No Matter In The Process Of Hot Stamping And Bumping After Bonding Plate, Or After Lifting Plate For a Period Of Time And Then Use, If Properly Operated, The Galaxy Etched Magnesium Plate Will Not Produce Deformation Phenomena Such As Edge Warping, Middle Bulging, Layout Distortion, Etc.

In The Production Industries Of New Year Pictures, Couplets, Lucky Characters, Invitations And Other Products, The Speed And Efficiency Of Hot Stamping Determine The Cost Of Products, And The Huge Production Quantity Produces Scale Benefit. Etching Magnesium Plate Has Been Used More And More Because Of Its Remarkable Advantages Of Fast Heat Transfer, No Distortion And High Printing Resistance.

In Drop Moulding, Leather Embossing, High Cycle Moulds, Heat Transfer Printing, Clothing Trademarks And Logo, Self-Adhesive Knife Moulds, Sole Moulds, Conference Logos, Door Logos, Medals, Nameplates, Product Trademarks, Badges, Braille Signs And Other Products, Etched Magnesium Boards Are Also Widely Used Abroad To Produce.

The Proportion Of Magnesium Is 1.738, Which Is Hexagonal Lattice Structure. The Proportion Of Magnesium Is 1/5 Of Copper And 1/4 Of Zinc. The Etched Magnesium Plate Has Advantages In Transportation, Installation, Bonding And Preservation Due To Its Small Mass And Light Weight.

Magnesium’s Heat Capacity Ratio Is Small, Heating And Cooling Speed Is Very Fast. In The Actual Process Of Hot Stamping, Etched Magnesium Plate Can Transfer Heat Rapidly In a Limited Time Through Conduction, Which Makes The Hot Stamping Effect Better And Brighter. In Addition, After a Single Hot Stamping, The Heat Of Etched Magnesium Plate Is Carried Out In Large Quantities, And The Temperature Is High. It Will Decrease Obviously, And The Volume Of Slightly Expanded Will Shrink, So There Will Be No Obvious Expansion And Deformation; While The Copper Plate After Heating, The Heat Dissipation Is Slow, The Volume Expansion Is Large, And The Edge Softening, Which Is a Remarkable Advantage Of Magnesium Plate Compared With Copper Plate. The Linear Thermal Expansion Rate Of Etched Magnesium Plate Is 26, That Of Copper Plate Is 17.5 And That Of Zinc Plate Is 36.

The Brinell Hardness Of Etched Magnesium Plate (Az31b Material) Is 110, Brass Plate (h59) Is 95, And Zinc Plate Is 49. The Surface Hardness Of Magnesium Plate Is Twice As High As That Of Zinc Plate, And Is Obviously Higher Than That Of Brass Plate. If It Is Az80 Corrosion Magnesium Plate, Its Surface Brinell Hardness Value Reaches 140.

The Etched Magnesium Plate Is Made Of Magnesium Alloy Sheet With 5 Micron Particle Size (99%) Which Is Fully Purified And Completely Crushed. The Composition Of The Material Is Uniform, Stable And Defect-Free. In Nitric Acid Solution, Magnesium Plate Can Be Uniformly And Uniformly Corroded.

In Magnesium Plate Corrosion Machine, Because The Reaction Between Etched Magnesium Plate And Nitric Acid Is Fierce And Fast, a Lot Of Heat Is Released, Accompanied By Yellow Gas. Yellow Gas Is An Oxidant Of Nitrogen. Attention Should Be Paid To The Exhaust Air In The Corrosion Machine. The Rapid Increase Of Temperature In The Machine Is The Heat Generated By The Reaction Between Magnesium Plate And Nitric Acid, Which Can Not Be Discharged In Time. The Treatment Method Is To Increase The Effective Refrigeration Capacity Of Refrigeration Equipment Or To Reduce The Initial Temperature According To Experience.

After Being Corroded By Nitric Acid, a Dense And Continuous Oxide Layer Can Be Formed On The Surface Of The Etched Magnesium Plate, Which Prevents The Internal Magnesium Metal From Continuing To React. Due To The Good Material Purification, There Is No Slag On The Exposed Surface Of Magnesium Plate (Slag Will React With Primary Battery, Further Corrosion Of Magnesium Plate), And It Will Not Be Corroded If It Is Placed In The Air For a Long Time.