Description

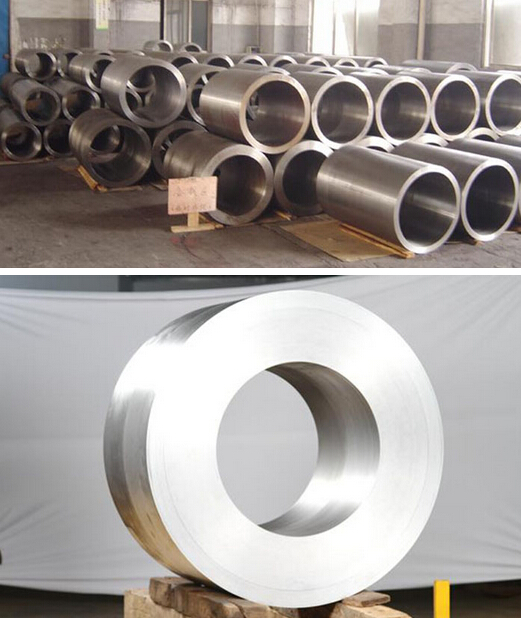

Forging Steel Parts Is a Kind Of Processing Method That Uses Forging Machinery To Exert Pressure On Metal Blanks To Produce Plastic Deformation To Obtain Forgings With Certain Mechanical Properties, Shape And Size. Forging (Forged And Stamping) Is One Of The Two Major Steel Forged Components.

Forging Can Eliminate The Defects Such As-Cast Looseness And Optimize The Micro-Structure Of Metals In The Smelting Process. At The Same Time, The Mechanical Properties Of Forgings Are Generally Better Than Those Of Castings Of The Same Material Because Of The Preservation Of Complete Metal Streamlines.

Forgings Are Often Used For Important Parts With High Load And Severe Working Conditions In Related Machinery, Except For Simple Rolled Plates, Profiles Or Weldments.

Materials We Can Choose As Below:

♠ High Quality Carbon Structural Steel: 20, 35, 45, 50, 55, 16Mn, 50Mn

♠ Carbon Tool Steel: T8 , T10

♠ Oil And Pressure Vessel Forging Steel : 16Mn, 20, 15CrMo, 20MnMo, 20MnMoNb, 35CrMo, 12Cr1MoV, 12Cr1MoV(P22), 14Cr1Mo, 20SiMn2MoV, SA-336F11CL3, SA-182F11CL3, SA-266/SA-266M, 25CrNiMo, 30CrMo, SA-336Cr.F22CL3, SA350-LF2, 21/4Cr1Mo

♠ Military Product Forgings: D406(30Si2MnCrMoVE)

♠ Power Station Forging: 26NiCrMoV14-5, 34CrMo1A

♠ Bearing Steel: GCr15, GCr15SiMn, G20Cr2Ni4A, GCr18Mo, 9Cr18Mo

♠ Alloy Structural Steel: 20~50SiMn, 40Cr, 42CrMo, 20~45CrMnMo, 45CrNiMnMo, 37SiMn2MoV, 40CrNiMoA, 40CrNi2MoA, 34CrNi3MoA, 34CrNiMo6, 30CrNiMo8, 20CrNi2MoA, 17CrNiMo6, 30Cr2Ni2Mo, 38CrMoA/A, 25Cr2Ni4MoV, 18Cr2Ni4W,

♠ Metallurgical Machinery Forgings Steel : 55Mn2, 60CrMnMo, 60CrNiMo, YB-15, 9Cr2Mo, 9Cr2MoV, 45Cr3NiMoV, 45Cr4NiMoV, 45Cr5NiMoV, 86CrMoV7, MC3, MC3A,

♠ Abrasive Steel : H13, B2, P20, 718, 5CrMnMo, 5CrNiMo.