Description

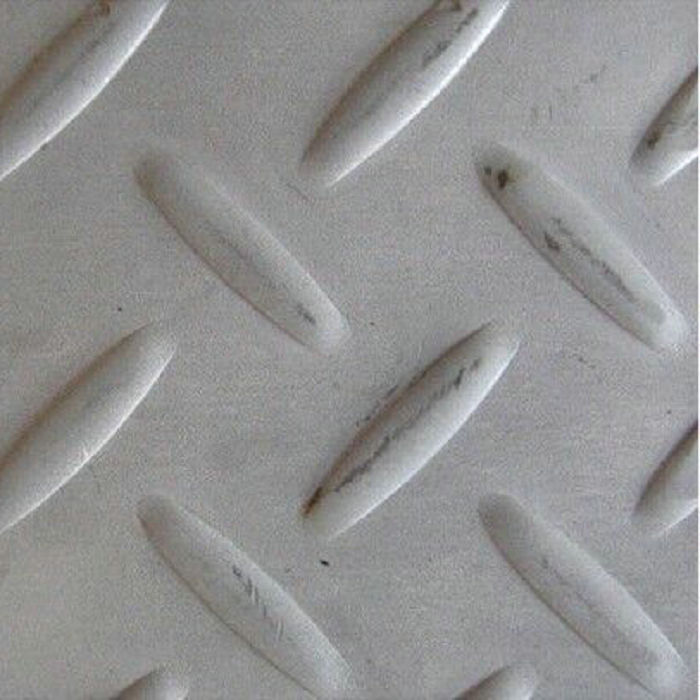

Sheet Metal Processing Steel Parts Be Shearing Buckling And Bending Forming

Sheet Metal Processing Is a Key Technology For Sheet Metal Technicians, And Also An Important Process For Forming Sheet Metal Products. Sheet Metal Processing Includes Traditional Cutting, Blanking, Bending And Forming Methods And Process Parameters. It Also Includes The Structure And Process Parameters Of Various Cold Stamping Dies, Working Principles And Operation Methods Of Various Equipment, As Well As New Stamping Technology And Process. Parts Metal Plate Processing Is Called Sheet Metal Processing.

Steel Sheet Metal Processing Is Called Sheet Metal Processing. For Example, Making Chimneys, Barrels, Oil Tanks, Ventilation Pipes, Elbows, Places Around The Sky, Funnel Shapes, Etc. With Sheet Metal, The Main Processes Are Shearing, Bending And Buckling Edges, Bending Forming, Welding, Riveting And So On, Which Require Certain Geometric Knowledge.

Sheet Metal Parts Are Sheet Steel Parts, Which Can Be Processed By Stamping, Bending, Stretching And Other Means. a General Definition Is Parts With Constant Thickness In The Process Of Processing. Corresponding To Them Are Casting, Forging And Pressing Parts, Machined Parts And So On.