Description

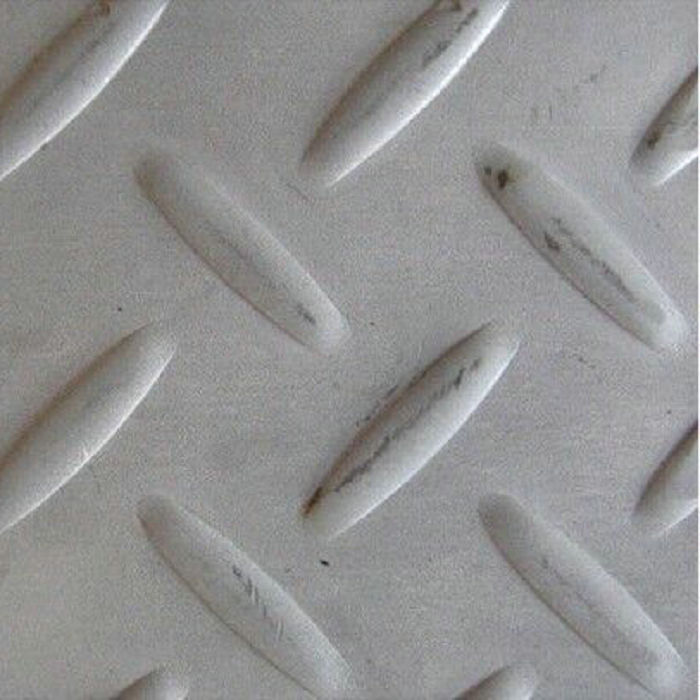

Stainless Steel Antiskid Plate Machining Anti Skidding Panels

Material: 304, 304L, 201, 321, 316L, 316, 310s, Etc.

Shape Of Hole: Crocodile Mouth, Small Ellipse 0, Round Convex Hole, Button Convex Hole, Fine Herringbone, Diamond, Etc.

Plate Thickness: 1-5mm

Features: Elegant Appearance, Corrosion Resistance, Acid Resistance, High Temperature Resistance.

Uses: Mainly Used In Chemical Industry, Building Decoration, Electrical Products, Kitchen Equipment, Food Equipment, Elevators, Stairs, Medical Equipment, Automotive Component Panels And Other Anti-Skid Equipment.

Stainless Steel Antiskid Panels Are Classified By Use

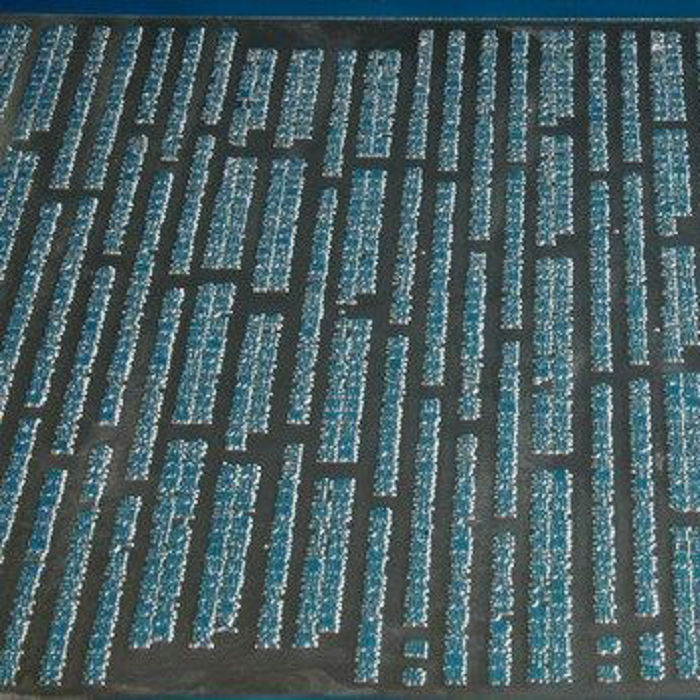

(1) Bridge Steel Plate (2) Boiler Steel Plate (3) Shipbuilding Steel Plate (4) Armored Steel Plate (5) Automobile Steel Plate (6) Roof Steel Plate (7) Structure Steel Plate (8) Electrical Steel Plate (9) Spring Steel Plate (10) Solar Special Plate (11) General And Mechanical Structural Steel Plate.

Microstructure By Steel Grade

(1) Austenite Type (2) Austenite-Ferrite Type (3) Ferrite Type (4) Martensite Type

Precipitation Hardening (Precipitation Hardening): Refers To a Heat Treatment Process In Which Metal Is Hardened By The Dispersion Of Solute Atoms In The Supersaturated Solid Solution And/Or By The Dissolution Of Particulates In The Matrix.

If Austenitic Precipitated Stainless Steel Is Precipitated And Hardened At 400-500 Or 700-800 Degrees After Solution Treatment Or Cold Working, High Strength Can Be Obtained. That Is, Supersaturated Solid Solutions Of Some Alloys Are Placed At Room Temperature Or Heated To More.